Itageo 6© is the most innovative software for the management of the automatic control station for the dynamic measurement of objects put in rotation on its axis. It allows the control of dimensional and geometric characteristics with results which are comparable to the measurements obtained with a roundness measuring instrument in a laboratory.

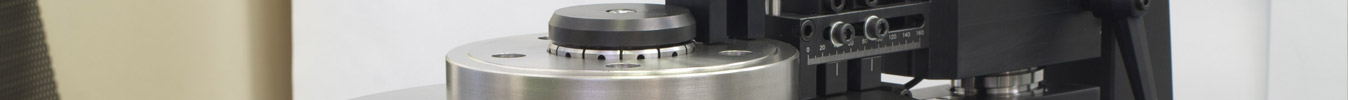

Itageo 6© is used for the dynamic control of objects put in rotation, and it’s normally used for the control of brake discs, brake drums, hubs, stubs, flywheels, friction discs, shafts, shafts for electric motors, etc… Itageo 6© is optimized for the dynamical controls and allows to control diameters with a single probe for each section. The result is the simplicity of the mechanical configuration and type change.

To guarantee the highest precision and reliability of the measurement, Itageo 6© works on the same measurement principles as laboratory roundness measuring instruments: a piece is put on rotation on a precision mandrel, angular control via encoder, a contact probe on each section to be measured, acquisition of at least 7.200 points/rotation for each section analysed, reconstruction and analysis of the obtained profile.

This technology allows:

• Visualization in real time of real profiles, big help in order to individuate possible causes of technical problems due to the production of the same pieces.

• Compensation of the rotation errors generated by the mandrel.

• Fourier Analysis, with decomposition of the form errors in single components, with the possibility of manage different tolerances for each error.

• Analysis of interrupted surfaces (fixing holes, ventilation holes, etc...).

• Possibility to implement harmonic filters and dirty filters for each section of the control plan, with different parameters.

• Possibility to analyse for sections of circumference : ex. Roundness each 30°.

The characteristics to be measured can be related to a single section (bar-to-bar, linearity, roundness, etc..) or resulted from the comparison of more sections (cylindricity, concentricity, Stack-Commutator Angle, etc..).

The use of the electronics of latest generation iDaq4Geo by TQM Itaca Technology allows the perfect synchronization between the probes and the encoder, optimizing the measuring performances.

Itageo 6© is able to manage the following functions:

1. Control of the production process.

2. Management of the cycle of Master Verification and automatic Master Resetting.

3. Data saving in SQL database, with fully network functionality.

4. Saving in the database of measures + profiles + Piece ID, to guarantee the traceability one by one.

5. Possibility to make a remote real time monitoring.

6. Management of remote tele-assistance.

7. Dialogue with external devices (load robot, frequencies control, cracks control, marking machines, processing machines, etc…).

8. Management of the marking of pieces.

The graphic interface simplifies the activities of the operators:

|

Immediate and visual configuration of the station. |

|

Creation of control plans with rapid and intuitive graphic support.

|

|

|

|

Definition of complex characteristics using the selection of the probes from the picture. |

|

User interface totally configurable: simple and immediate, with the global result of the test (green for good, red for reject and yellow for uncertain), punctual values for each characteristic of the control plan and possibility to display up to 6 graphics for the critical sections. |

|

|

|

Display of complex geometrical characteristics in 3D mode. |

|

|