Itanoise© is the system for the measuring of the noise of mechanical components during their functioning.

It can be used in laboratory or directly in a production line for the 100% control of the produced components.

The equipment is composed of:

• Software Itanoise©

• PC

• Sensor Box Idaq4Sonic

• Power supply iPower4Sonic

• Sensor – Accelerometer, Automatic Accelerometer, Microphone.

The choice of the sensor depends on factors like:

• Working environment: verification of the influences external to the test (noise, vibrations, etc…)

• Type of the control: in line for 100% control or in laboratory

• Time available for the execution of the test

• Complexity of the control system

Software Itanoise©

The software is entirely developed by TQM Itaca Technology and it is easy and intuitive.

It has the same logic structure as Itageo, Itasonic, Itastat, with batches and measuring programs.

There are available different analysis mode:

|

Third octave analysis |

In the picture above it’s shown the sonic imprint revealed by 2 sensors: to channel 1 is connected an accelerometer – in the picture it’s represented by the light green graph, and to channel 2 is connected the microphone – in the picture it’s represented by the grey graph. The analysis is made in third octave: it’s possible to note the tolerances diversified for the 2 sensors, and different for each frequency. Note in the last column on the right the dbOverall values of the 2 sensors.

|

Analysis in the time domain |

In this image the sound recorded for 2 seconds is represented in the time domain: it’s possible to clearly discern 5 peaks from the background noise.

|

FFT Analysis |

In this graph it’s possible to see highlighted all the single frequencies which compose the sonic spectrum acquired during the test.

|

Individual values chart for each frequency |

In this image are represented the individual values charts of the two characteristics: dbOverall sensor 1 and dbOverall sensor 2 measured on 73 pieces. The result of the test, at the right bottom, is total and it considers all the analysed frequencies.

Main features:

• Data saved in Itastat6 database in SQL format

• Users management with operator permissions

• Auxiliary Data management

• Menu for the station configuration

• Guided creation of the control plans/measuring programs, where define all the parameters of the test

• Possibility to manage up to 4 sensors at the same time

• Noise analysis in octave and in one-third octave, with tolerances which can be defined for each frequency

• Automatic calculation of the tolerances on the base of the pieces defined “Good”

• Measure in db and in dbA

• Measuring of the db Overall for each sensor used

• Configurable duration of the test

• Availability of an advanced Transfer Function in order to compare the measures made by different sensors

• I/O management for the interfacing with the line and/or with the load system

• Possibility to manage the piece ID, both from the keypad and from readers integrated in the bench

• Large possibility to personalize Hardware and Software

• Hardware components easily integrable in existing lines

• Special contact sensors, with automatic activation, studied for the use in 100% control.

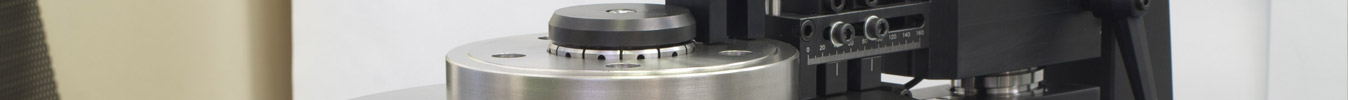

Itanoise© is available in manual version for laboratory and in automatic version to be integrated in existing lines.

It’s possible to realize complete test stations, with load/unload system, piece clamping, power supply, automatic test cycle, unloading after test and separation good/reject.