Nowadays it’s necessary to measure what it’s produced. But often measuring is not sufficient: it’s necessary to manage and organize in a rational way the available measures in order to reduce at the minimum the costs and optimize the utility.

|

|

The picture outlines the main functions of the software modules for the collection and the management of the measuring data.

The measures can come from the metrological room or from the production lines; in the metrological room they are collected by the software Itaconv 6, which reads the file coming from the instruments and writes the control plans and the measures in the database of Itastat 6.

In the production line the data can be collected from SPC stations managed by the software Itastat 6 Measure or from special stations which can be also provided with personalized special software.

The data coming from the production line are saved in the same database of Itastat 6.

The data can be object of statistical analysis (software Itastat 6 Analysis). It’s possible to make very detailed selections and stratifications (software Itaselect) and also make the monitoring in real time of all the stations connected to the database (software Italarm).

In the following images some examples.

|

|

| Example of instruments (with PC and with files generation) which can be interfaced using Itaconv 6. |

|

|

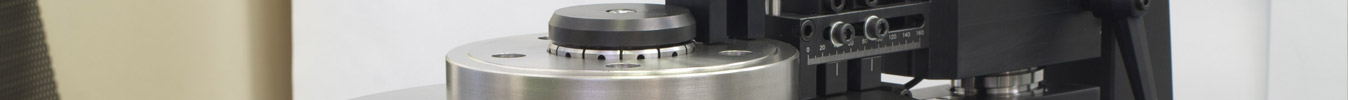

| Example of instruments which can be interfaced to a SPC Itastat Measure station. |

|

|

| Example of a structure for the data collection with metrological room, production line, quality department, database on a server, monitoring with direct interaction on work stations. |