Itastat 6 Measure is the SPC software module for the acquisition of the measures from keyboard or directly from manual instruments used in a workshop: provided with simple and complete operator interface, it allows to increase the measuring with useful auxiliary data. It’s possible to make compulsory the registration of Operator’s Notes or of pre-configured Events, which can be linked to Causes and Remedies in correspondence of values out of tolerance or in case of statistical alarms. It’s possible to set the request of sampling at predefined intervals, the phases of sampling with different frequencies are managed in the same control plan. Itastat 6 Measure can be managed using a programmable operator keyboard, and it’s possible to use a pedal for the confirmation of the measure. It writes the data directly in the SQL database of Itastat 6, which can be centralized on a server. Itastat 6 Measure manages possible network failures automatically inverting the acquisition on a local database.

Itastat 6 Measure can be integrated with 2 optional modules which allow the management of documents and images:

- Lay Out Designer. It’s the module which allows the total configuration of the operator interface. So, it’s possible to display drawings, pictures etc… related to the pieces to be measured or to the operations to do, etc.. for each measuring phase of each control plan.

- Doc Viewer. It allows to univocally link documents (max 8) of different formats (pdf, dwg, dxf, doc, xls, txt, bmp, tiff, jpg, png, mpeg, avi, etc.) with each control plan: the linked documents (technical drawings, control instructions, production instruction, etc…) are recalled by the operator keyboard. It needs the network connection of the measuring stations.

|

|

|

| Example of operator interface with control charts for characteristic, and coloured bars to exactly display each executed measuring. | Example of operator interface without graphs but with extended bars. |

|

|

|

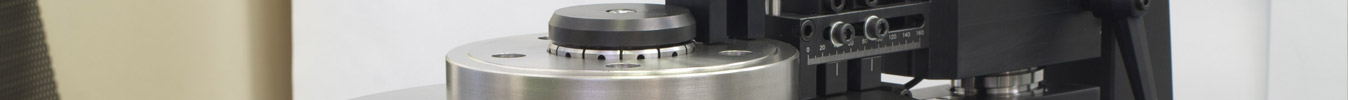

| Example of operator interface with option Lay Out Designer, which allows to personalize the display for each phase of the control cycle. |