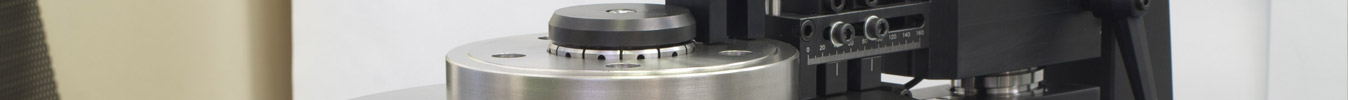

TQM Itaca Technology has developed a dedicated measuring system for brake disk and drums that performs automatic re-tooling of the measuring probes on the bench.

This concept can be applied also to many other systems manufactured by the company, that share the functioning as "Shopfloor roundness machine".

Moreover, the purpose is to connect all the production and measurement systems in the line to obtain a "Industry 4.0" mode of functioning, where all the instruments and machines are connected togethere to share data and change the workflow depending on the specific request.

This automatized mode of functioning has been developed to fullfill some customer demand, as:

- Increase the automatization degree in the system;

- Simplify the re-tooling operations;

- Increase precision and repeatibility of the measurements.

- Decrease the tooling operations and intervention lenght.

All these operations are possible using precision electric and pneumatic actuators that can set the probe position depending on the measure program or the part code.

The system can be included in a production line or in a robotic processing island to be managed by robot or other loading systems.