For the control of brake drums, TQM Itaca Technology has developed stations complete of mechanics and software, called Itageo 6©. These stations, also called “Workshop Roundness Measuring Instruments”, measure the drums with the same logic of a laboratory roundness measuring instrument, obtaining comparable results, with cycle time of about 15 seconds. The management of more probes at the same time allows to have very complex control plans without influencing the cycle time. It’s provided the automatic management of the verifications and master resetting, for the control of the gauge stability.

The measuring cycle is completely automatic, also in the version with manual loading/unloading.

The stations can be retooled, can be integrated with FRF control (Natural vibration frequencies), with marking systems to guarantee the 100% traceability, with cracks control with Eddy Current technology.

There are available different configurations, in order to insert the gauge in any type of production line. The stations can be served by anthropomorphic robot or supplied with load/unload portal . In the scheme below there are the characteristics which can be measured with the gauges Itageo 6©.

Measuring Principles

The measuring software Itageo 6© is optimized for the dynamical control of objects put in rotation, and it allows to control diameters with a single probe. The result is the simplicity of mechanical configuration and type change.

To guarantee the highest precision and reliability of the measurement, Itageo 6© works on the same measuring principles as the laboratory roundness measuring instruments: the piece is put in rotation on a precision mandrel, angular control via encoder, one contact probe on each section to be measured, acquisition of at least 7.200 points/turn for each section analyzed, reconstruction and analysis of the obtained profiles.

The analysis of the profiles allows:

• Display in real time of the profiles, a great help to identify the possible causes of technical problems due to the processing of the same pieces.

• Fourier Analysis, with breakdown of the form errors in the single component, with possibility to manage different tolerances for each error.

• Possibility to implement filters like the roundness measuring instrument.

• Possibility to implement dirty filters.

• Possibility to analyze for sections of circumference : ex. roundness every 30°.

• Possibility to compensate the rotation errors induced by the mandrel.

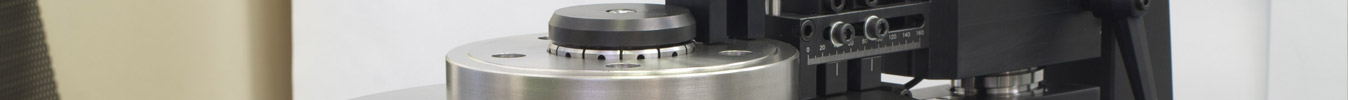

The mechanics

The drum is put on a precision mandrel, with three supporting plans placed at 120°, and three locking jaws, placed at 120°, out-of-phase respect to the supports. The internal probes, for the measuring of the supporting plan, of the central hole, of the braking surfaces, etc… are contained in special interchangeable masks which allow a fast type change and which ensure the correct positioning of the probes. The external probes, which can be all easily repositioned, are mounted on an automatic slide that during the load/unload phases is out of work area. The slide is equipped with an anti-collision safety system.

The software Itageo 6©

Itageo 6© is the most advanced software for the management of automatic stations for the control of brake discs and brake drums. It is able to manage the following functions:

1. Management of dynamic, geometric and dimensional measurements of brake discs and brake drums.

2. Immediate and visual configuration of the station.

3. Creation of control plans with rapid and intuitive graphic support.

4. Definition of complex characteristics through the selection of probes with visual support.

5. Simultaneous display of up to 6 graphs for the critical sections.

6. Display of complex geometric characteristics in 3D mode.

7. Total configurability of the user interface.

8. Control of the interrupted surfaces.

9. Control of the production process.

10. Use of an algorithm for the compensation of the perpendicularity errors of the mandrel.

11. Harmonics Analysis (Fourier Analysis) with possibility to verify every single harmonic, each with its own tolerances.

12. Cut-off filter of the high frequency harmonics.

13. Settable dirty filter.

14. Management of the cycle Master Verification and Automatic Resetting Master.

15. Direct saving in SQL database, with full functionality in network.

16. Possibility of remote monitoring in Real Time.

17. Management of tele-assistance in remote.

18. Dialogue with external devices (loading robot, marking machines, processing machines, etc..).

19. Management of marking and traceability of the parts.